With us, you won't be left wondering

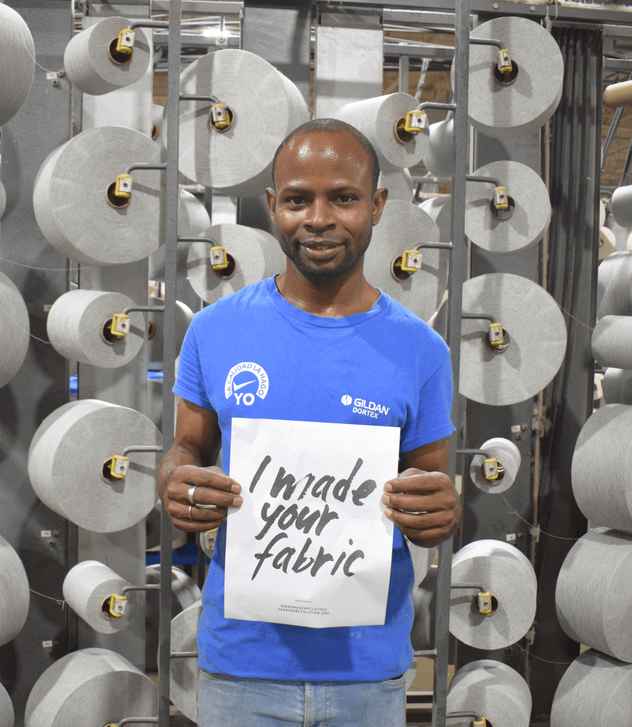

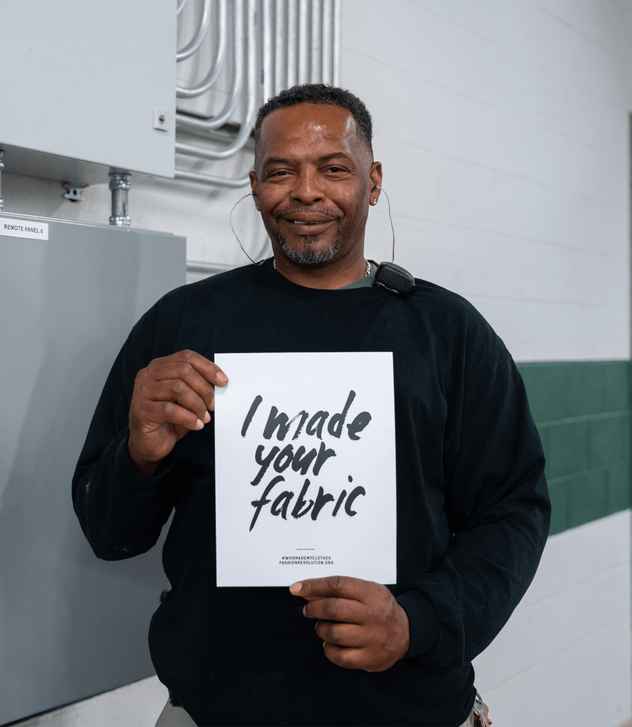

Meet some of the workers that make our products: from yarn spinners, to dyers, to sewing operators, to packagers, and transporters. Because our philosophy is simple, everywhere we operate, we make it a priority to treat our employees with respect and to provide them with safe and ethical work environments.

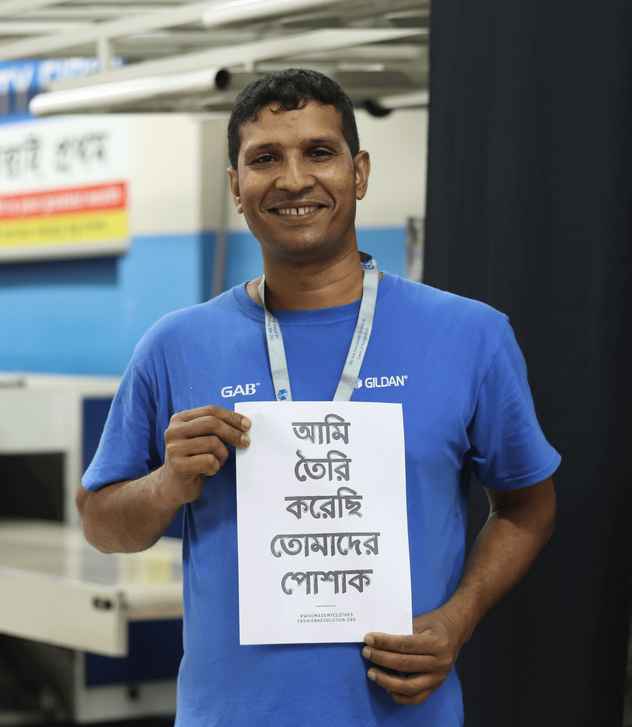

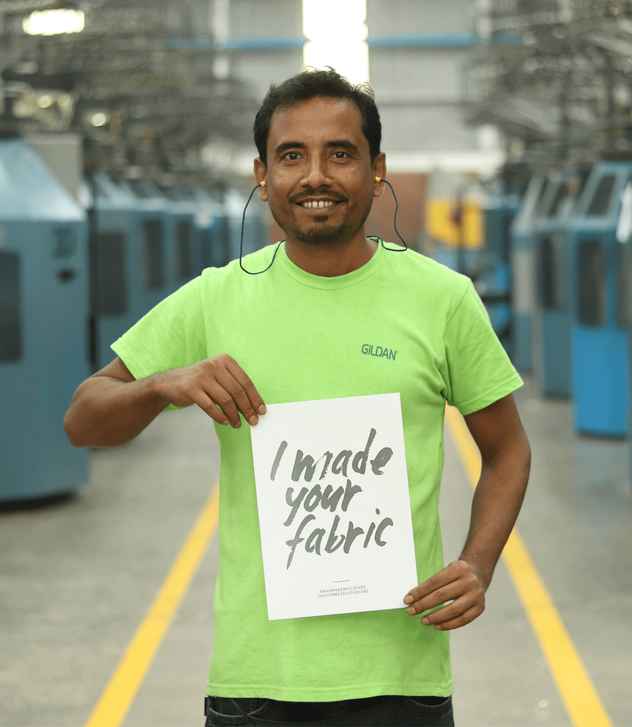

Since 2013, Fashion Revolution has called upon citizens to demand greater transparency from brands by asking #WhoMadeMyClothes? This year, Fashion Revolution asks a second question: #WhoMadeMyFabric?

“Fashion Revolution has created a powerful reminder for customers to think beyond the end product and about the people who make their clothes at different stages of the production chain. Because we own our supply chain, from spinning our yarns, to textile making, sewing, and distribution, this campaign is a great opportunity for us to highlight our respect for our people and transparency, which has always been a longstanding priority for us and core to our business.”

The people behind our apparel

Every year, we publish small features of our factory employees from our facilities in Honduras, Nicaragua, Dominican Republic, Bangladesh, and the United States on our social media channels and website to show the people behind our apparel. Stay tuned on Facebook, Instagram, Twitter, and LinkedIn to meet some of Gildan’s employees who are behind Gildan’s vision of Making Apparel Better®.

Meet Barry

Meet Barry, one of our opening room operators at our yarn-spinning facility in Eden, North Carolina. When asked about a standout moment he’s had while working at Gildan, he said “my wife bakes pound cakes and one time my friend at Gildan asked me to bring one of my wife’s cakes to work. I did and everybody here loved it! There was a feeling of joy in the facility from everyone.”

Meet Jaqueline

Meet Jaqueline, a sewing operator at our Chinandega sewing facility in Nicaragua. She has been with us for 2 years and is responsible for sewing pieces of fabric together to create our final product. If you own a Gildan product, it’s possible Jaqueline sewed it for you!

Meet Deyvi

Meet Deyvi, a cutting operator at one of our textile facilities in Honduras. For the last 7 years, he has been responsible for cutting our rolls of fabric into pieces of clothing that will later be assembled at our sewing facilities.

Meet Mohammad

Meet Mohammad, one of our senior cutting operators at our textile facility in Bangladesh. Once our fabric is dried and compressed, Mohammad uses a small robot to cut fabric into pieces of clothing. These pieces are then sent to our sewing floor to be sewn into high quality products! He has been doing this at Gildan for over 13 years and we are very lucky to have his expertise on our team.

Meet Yafreysy

Meet Yafreysy, a training operator at our textile facility in the Dominican Republic who has been working at Gildan for 15 years! When asked what her favourite part about working at Gildan is, she said “Gildan is a company of opportunities and growth. In the years that I’ve worked here, I have taken training courses offered to employees and that has helped me grow into my role as a trainer.”

Meet Lisa

Meet Lisa, our supply coordinator at our yarn-spinning facility in Salisbury, North Carolina. For over 8 years, Lisa has been responsible for inventory and stock of machine parts, ordering new machines or parts for repairs, purchasing and receiving orders, and so much more. The diversity of her job is one of the many things she loves about working at Gildan!

Meet Nelson

Meet Nelson, one of our automatic systems coordinators in Honduras, who has been with us for 15 years! Initially starting as one of our textile operators, he now works building recipes for our textile dyeing processes.

Meet Pureza

Meet Pureza, one of our robot technicians at our yarn-spinning facility in Mocksville, North Carolina. She has been working here for 6 years, and when asked about why she likes working for Gildan, she said “working as a robot tech brings a lot of diversity in my role. I can go to different parts of the facility and work on different machines, which I love.”

Meet Md. Badsha

Meet Md. Badsha, one of our assistant knitting operators at our facility in Bangladesh. He’s been working here for over 2 years and is responsible for ensuring that our yarn gets knit into rolls of fabric!

Meet Milton

Meet Milton, a packing station operator who has been working at our yarn-spinning facility in Sanford, North Carolina for 24 years! When asked about his life at Gildan, he said “I love working with the people here, and the management is great. When I won employee of the month, it made me feel recognized, valued, and validated. Gildan has got to be the greatest place to work!”

Meet Juan

Meet Juan, a textile operator at our facility in the Dominican Republic. He has been working at Gildan for over 2 years, and he is very grateful for all the opportunities he’s had with us. We are very grateful for all his hard work!

Meet Frank

Meet Frank, one of our drawing overhaulers at our facility in Sanford, North Carolina. He’s been working here for 8 years. Here is what he has to say about his life at Gildan: “good management makes you feel at home while you’re working. And at Gildan, that’s exactly how it feels.”

Meet Jorge

Meet Jorge, one of our overhaulers at our yarn-spinning facility in Salisbury, North Carolina. He has been working with us for 4 months and has already made many friends at Gildan. It just so happens that his wife, his brother, his father, and his mother-in-law work at this facility too!

Meet Marcos

Meet Marcos, a sewing operator at our San Marcos sewing facility in Nicaragua. He has been working with us for 13 years and when asked about his favorite part about Gildan, he said “I love having the opportunity to spend time with my family, while also being able to provide for them.”

Meet Antonia

Meet Antonia, one of our tab operators at our yarn-spinning facility in Salisbury, North Carolina. For the last 6 years she has been working at Gildan. Whenever there is a new hire at the facility, she loves to help them out. In fact, she recently got named Employee of the year and the feeling of recognition is unbeatable she said.

Meet Oliujjaman

Meet Oliujjaman, one of our cutting operators at our textile facility in Bangladesh. For almost 5 years, Oliujjaman has been cutting our fabric to create different pieces of garments that will eventually be sewn together.

Meet Martin

Meet Martin, one of our spinning technicians at our yarn-spinning facility in Sanford, North Carolina. For the last 11 years, Martin has been ensuring that our machines are operating efficiently. He loves what he does, but the people he works with makes his job even better, “my coworkers have become my friends.”

Meet Reggie

Meet Reggie, one of our electricians at our facility in Sanford, North Carolina. Reggie has been at this facility for the past 23 years, and when asked about his life at Gildan, he said “I love working with all my coworkers. It makes the day go by quickly and we always have a good time together.”

Our goal

We hope that by answering this call-to-action, we help ignite a global conversation about supply chain transparency and start to inspire you to think differently about what you wear. Because wearing clothes feels better when you now that the people who made them received fair wages, good benefits, and were empowered to share in the company’s success.